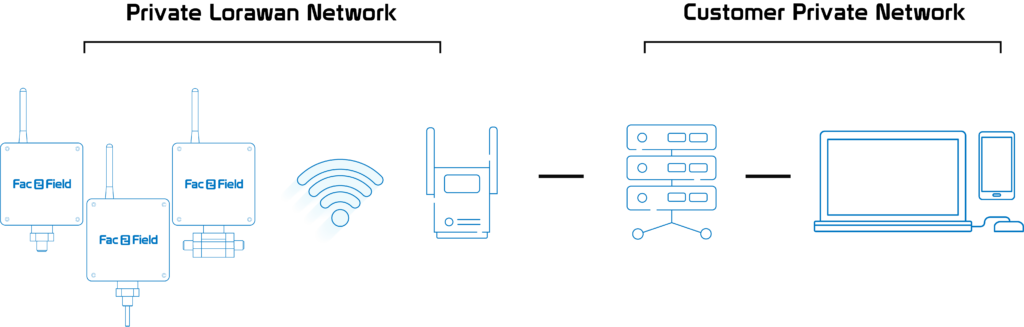

LoRaWAN® Architecture

The LoRaWAN® is a Low Power Wide Area (LPWA) networking protocol designed to connect battery wirelessly operated ‘things’ to the internet in regional, national, or global networks. It targets key Internet of Things (IoT) requirements such as bi-directional communication, end-to-end security, mobility, and localization services.

The LoRaWAN® architecture has three basic levels for each type of device and functions over the network, coming from the end devices to the network server providing a secure infrastructure to deliver field data to the customer application infrastructure.

LoRaWAN® Devices

Features

- Features Small pressure sensor.

- Fully digital signal processing, stable and reliable.

- Suitable for large-scale data acquisition andautomation control systems.

- Crude oil, wet and natural gas process.

- Lorawan transmission protocol.

- Battery operated with up to five years ofautonomy with a reading frequency of one hour.

Aplications

- Oil and Gas industry.

- Petrochemical industry.

- Power generation.

- Hydraulic / pneumatic system.

- Water treatment system.

- Automation equipment.

- Industrial process.

Features

- Features Small pressure sensor.

- Fully digital signal processing, stable and reliable.

- Suitable for large-scale data acquisition andautomation control systems.

- Crude oil, wet and natural gas process.

- Lorawan transmission protocol.

- Battery operated with up to five years ofautonomy with a reading frequency of one hour.

Aplications

- Oil and Gas industry.

- Petrochemical industry.

- Power generation.

- Hydraulic / pneumatic system.

- Water treatment system.

- Automation equipment.

- Industrial process.

LoRaWAN® Devices

Features

- Features Small pressure sensor.

- Fully digital signal processing, stable and reliable.

- Suitable for large-scale data acquisition andautomation control systems.

- Crude oil, wet and natural gas process.

- Lorawan transmission protocol.

- Battery operated with up to five years ofautonomy with a reading frequency of one hour.

Aplications

- Oil and Gas industry.

- Petrochemical industry.

- Power generation.

- Hydraulic / pneumatic system.

- Water treatment system.

- Automation equipment.

- Industrial process.

Wireless Remote Monitoring & Control Solutions

Wireless Remote Monitoring & Control Solutions

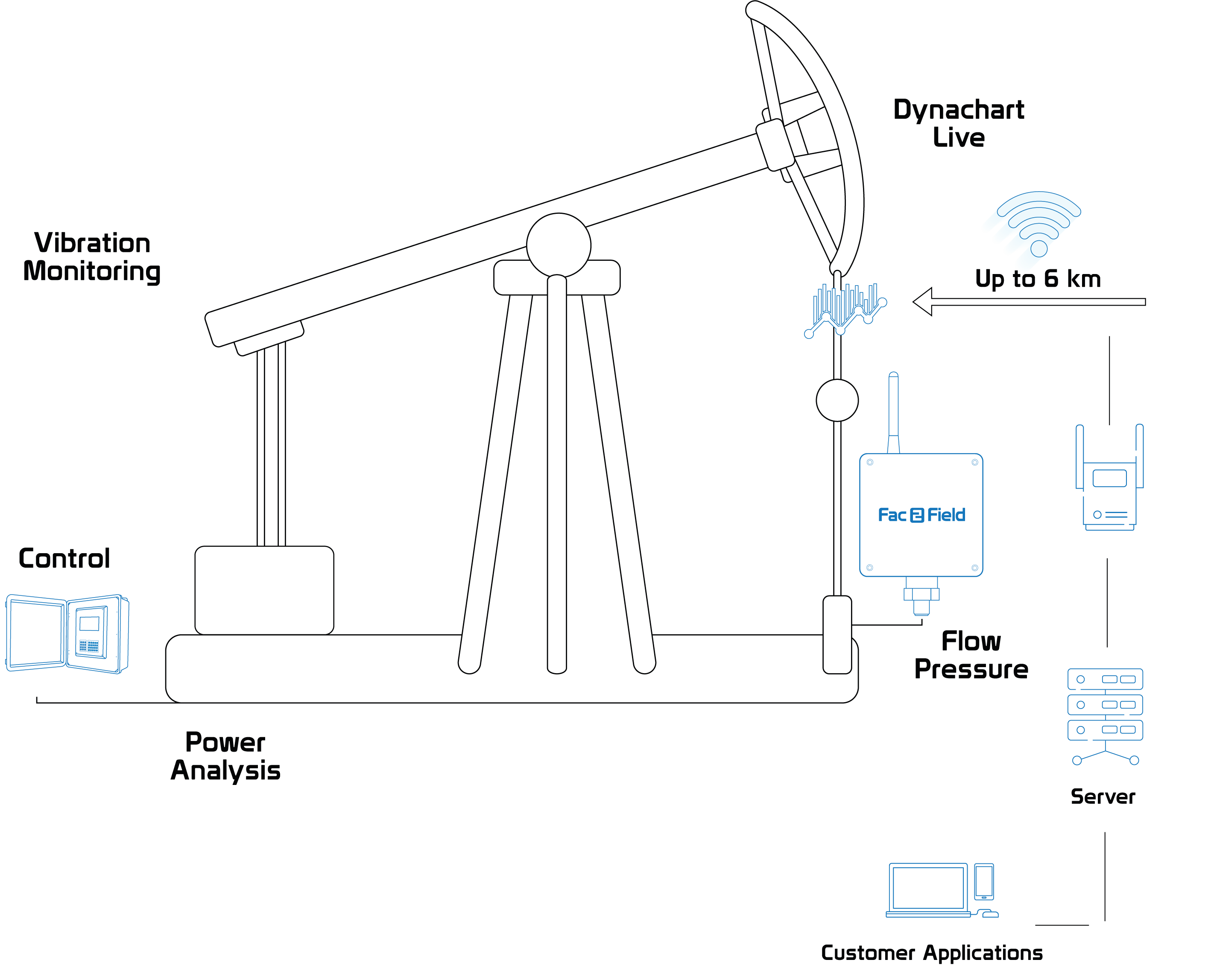

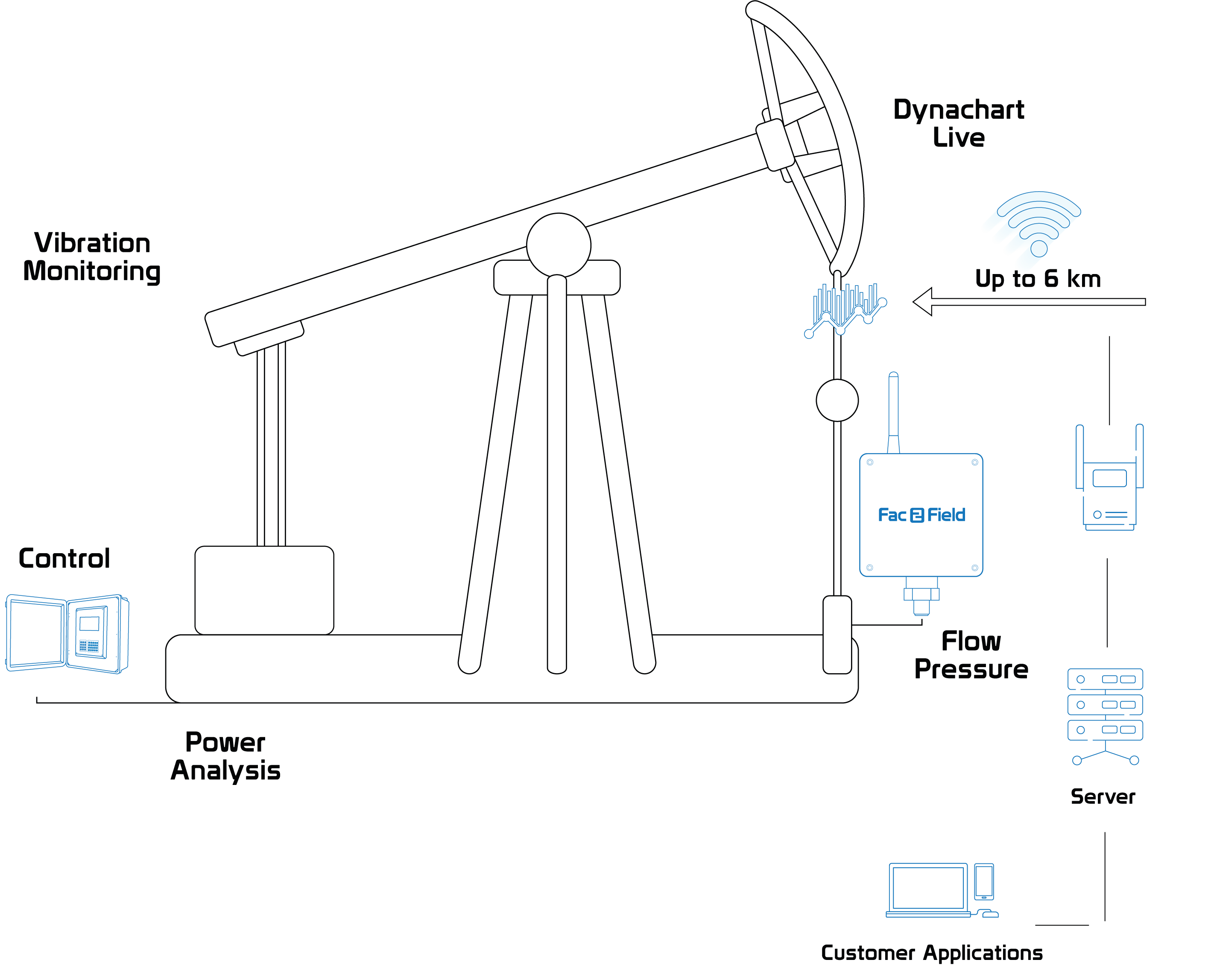

Sucker Rod Pump Monitor and Control

- Wireless Power, Load, and Position Analysis

- AI algorithms to develop real-time Dynagraph and Power charts.

- Transmission through the client’s LoRaWAN network.

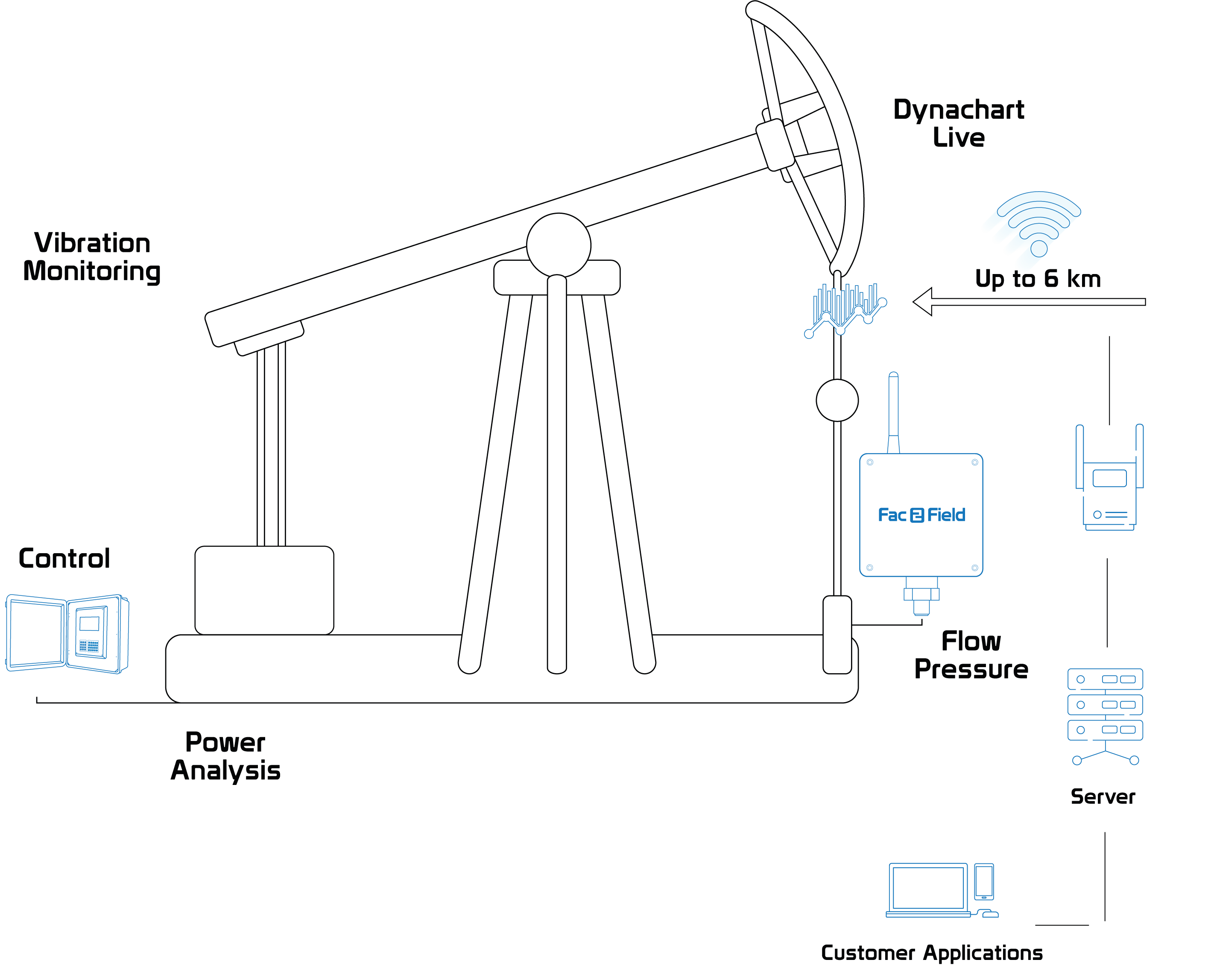

Sucker Rod Pump Monitor and Control

- Wireless Power, Load, and Position Analysis

- AI algorithms to develop real-time Dynagraph and Power charts.

- Transmission through the client’s LoRaWAN network.

Sucker Rod Pump Monitor and Control

- Wireless Power, Load, and Position Analysis

- AI algorithms to develop real-time Dynagraph and Power charts.

- Transmission through the client’s LoRaWAN network.

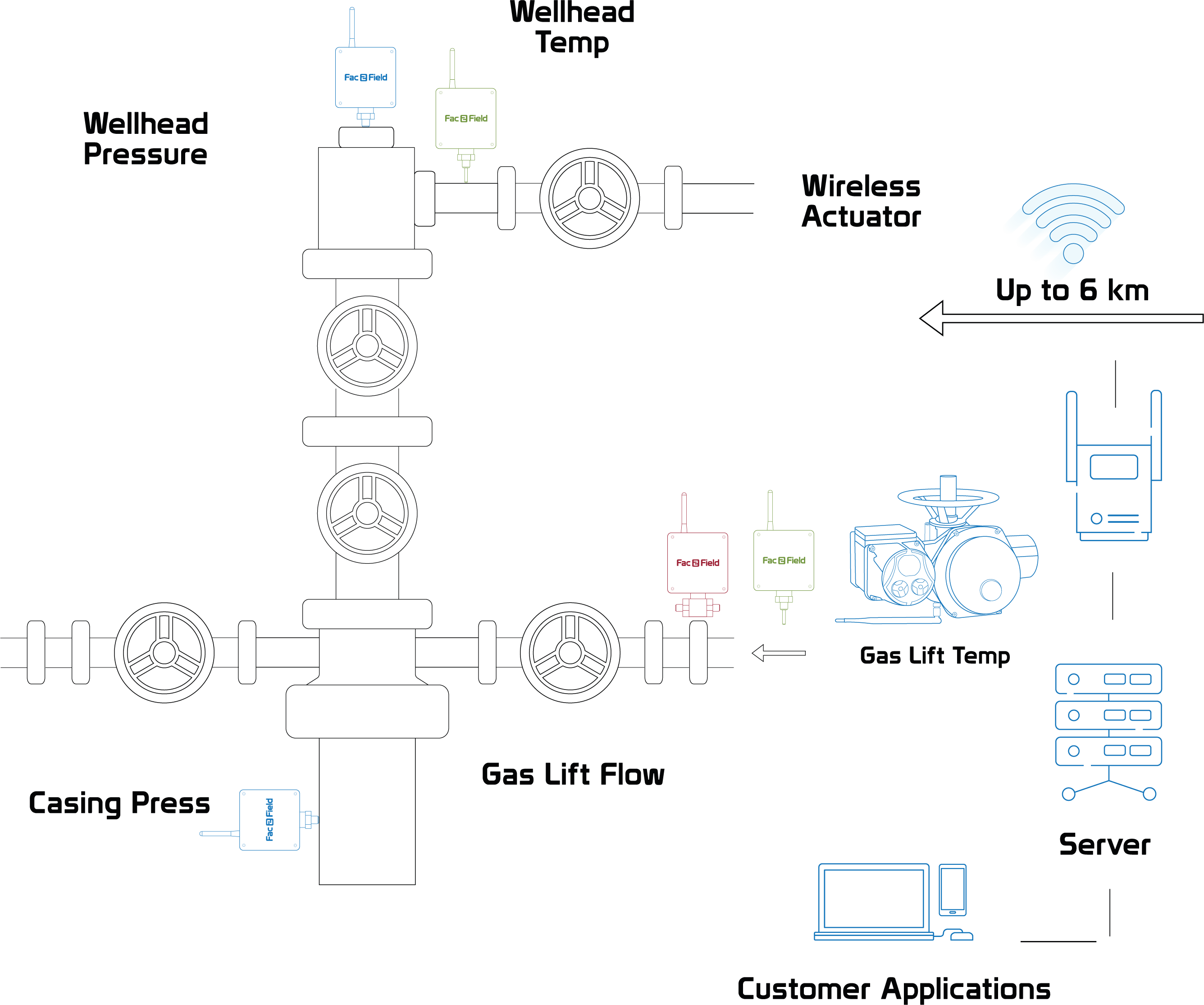

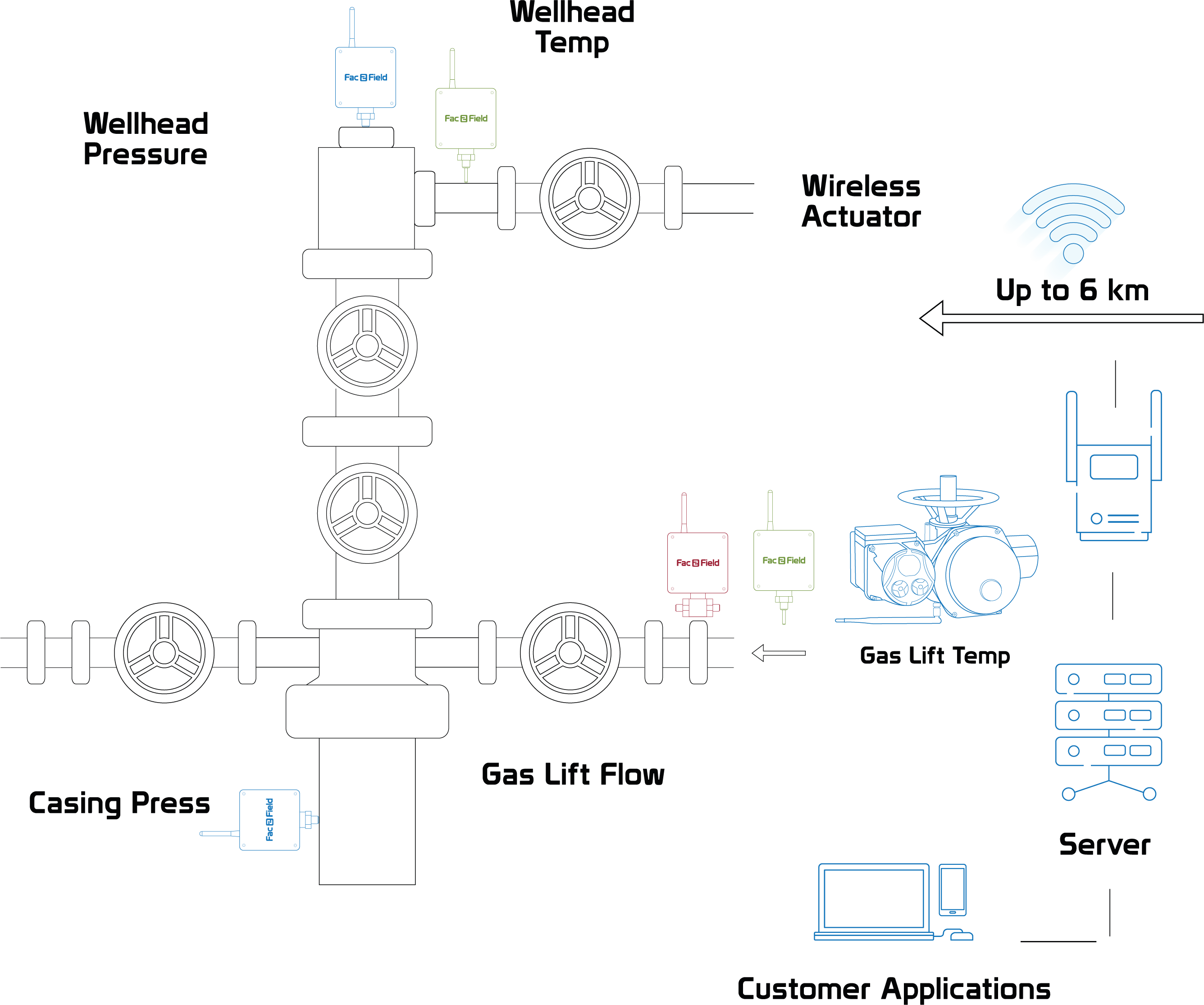

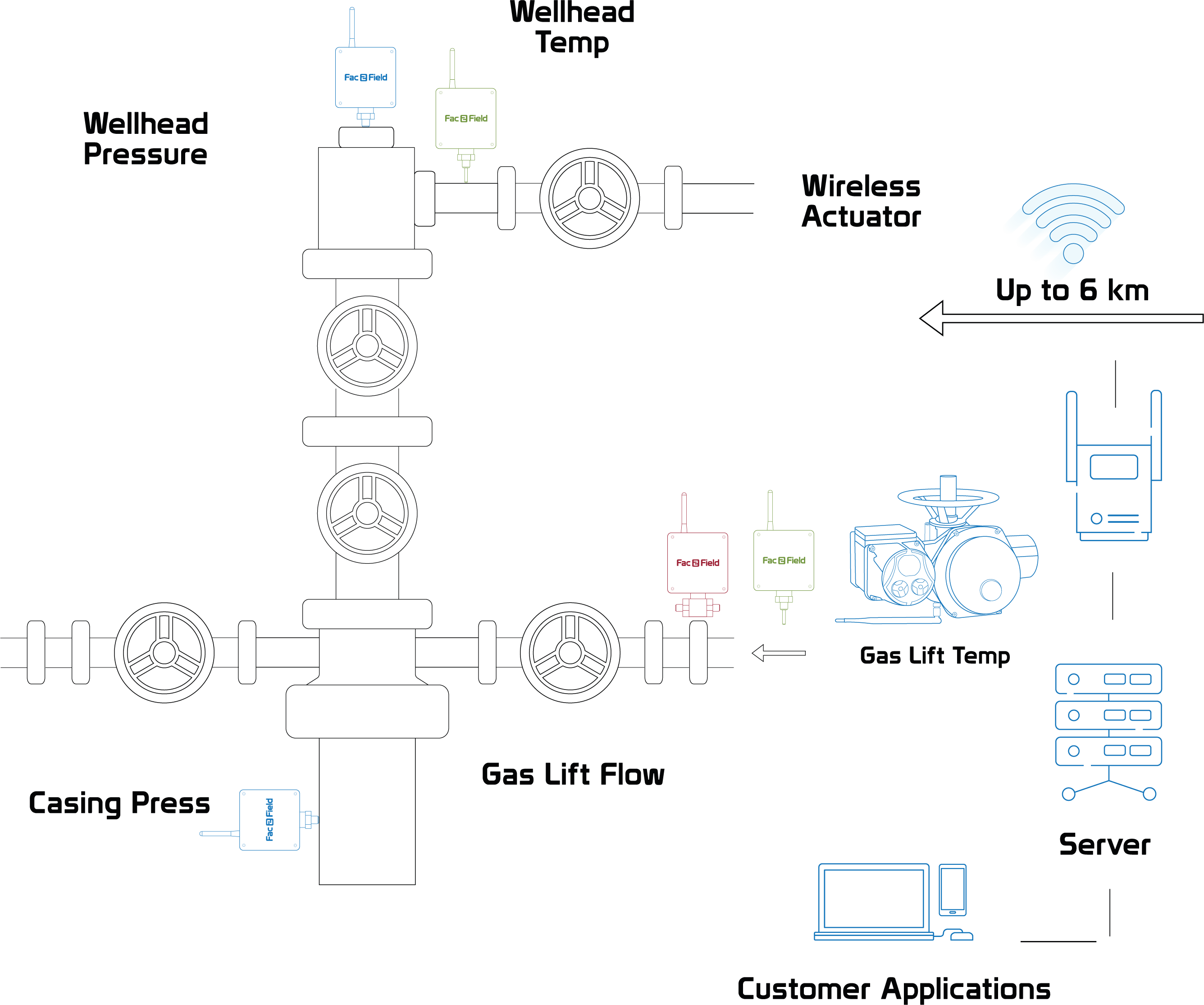

Gas-Lift Wells Monitor and Control

- Monitors all Well parameters and controls the gas injection actuator remotely.

- The Actuator. Electronics and the Field Communication transceiver come together in a compact pack(pre-installed). So, no cabling is required on site.

- Additional Sensor Devices installed in the Well give real-time monitoring of Well Parameters.

- Full Solution does not require cabling.

Gas-Lift Wells Monitor and Control

- Monitors all Well parameters and controls the gas injection actuator remotely.

- The Actuator. Electronics and the Field Communication transceiver come together in a compact pack(pre-installed). So, no cabling is required on site.

- Additional Sensor Devices installed in the Well give real-time monitoring of Well Parameters.

- Full Solution does not require cabling.

Gas-Lift Wells Monitor and Control

- Monitors all Well parameters and controls the gas injection actuator remotely.

- The Actuator. Electronics and the Field Communication transceiver come together in a compact pack(pre-installed). So, no cabling is required on site.

- Additional Sensor Devices installed in the Well give real-time monitoring of Well Parameters.

- Full Solution does not require cabling.

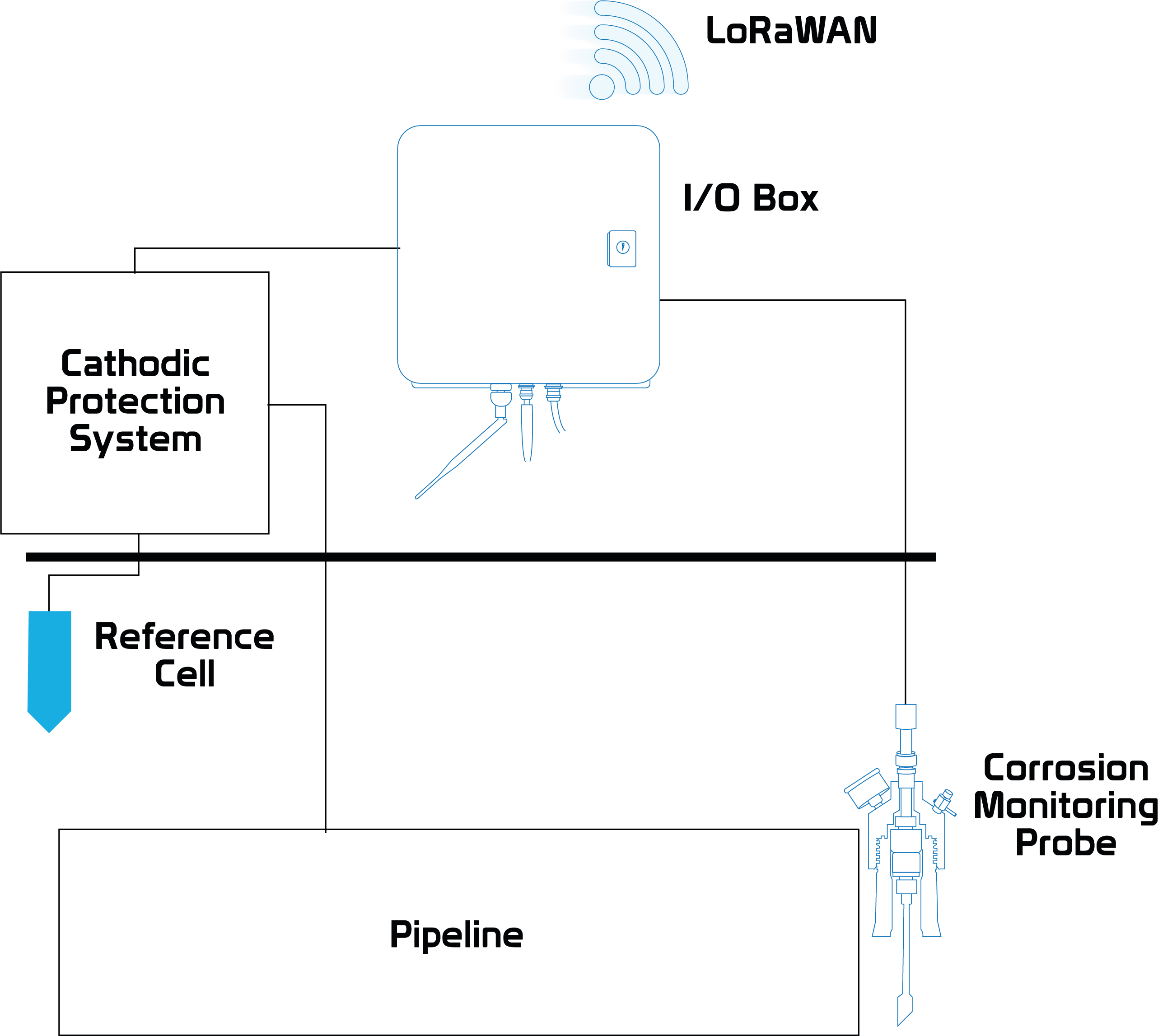

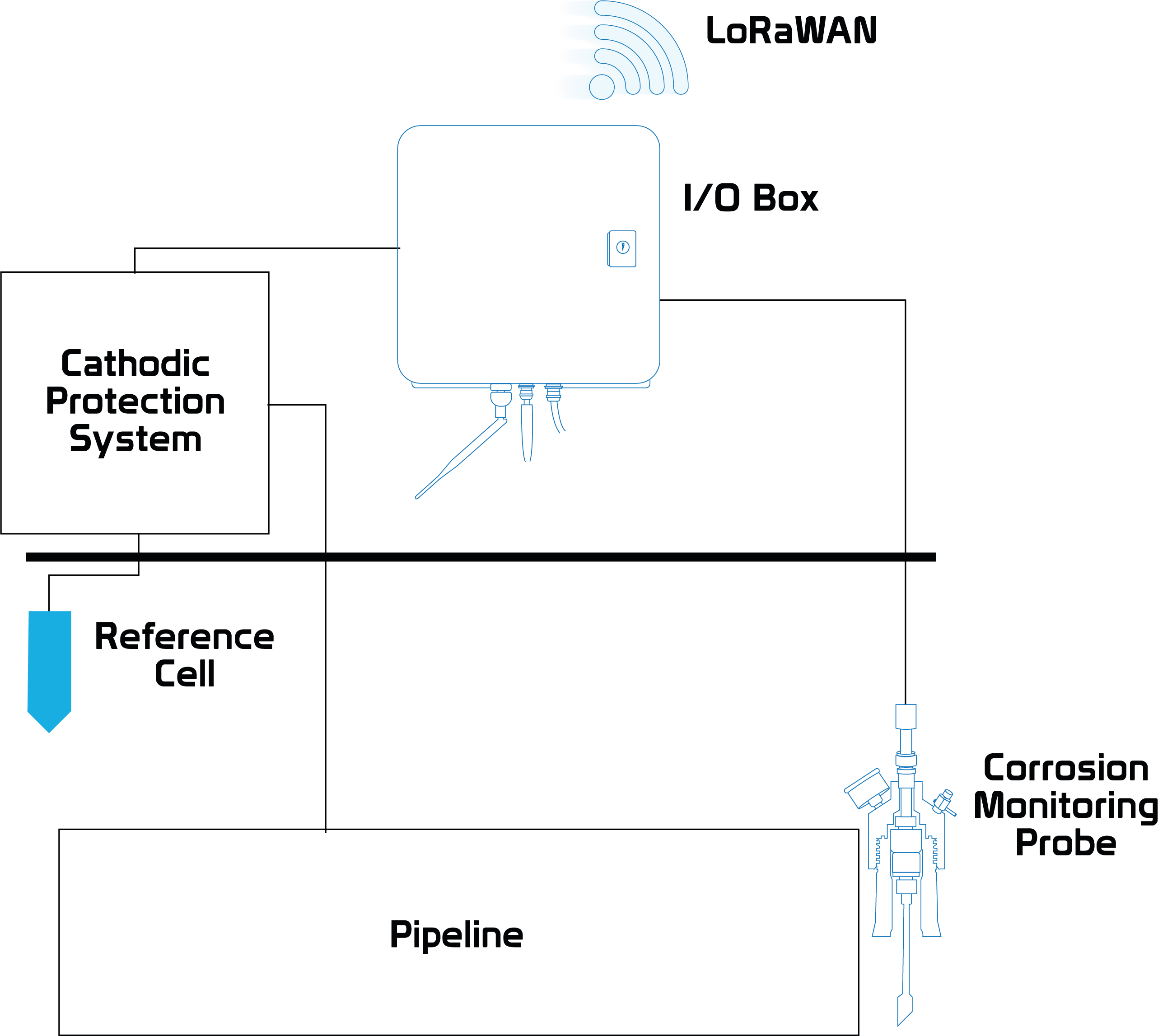

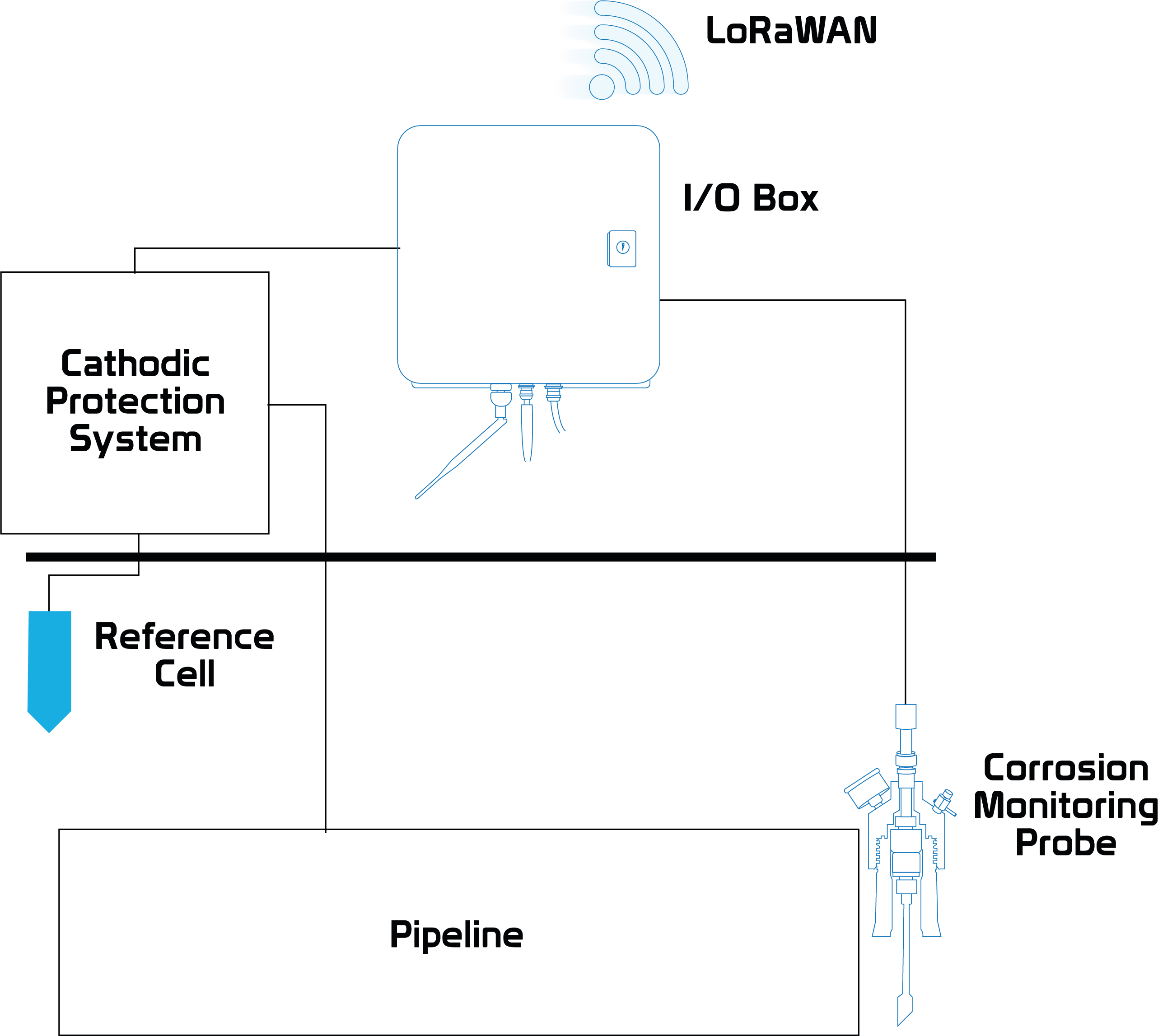

Corrosion Monitoring

Information Provided

- Protection Levels Estimation, Service interruptions, Breakdowns, Anode/bed depletion, fault in cables or connections, CPS effectiveness, faults in cables or connections.

- Optional1: anticipated corrosion rate in the medium.

Variables Measured

- Cathodic Protection Controller Output Voltages and Currents (DC).

- Cathodic Protection Controller Half-Cell Voltage.

- Power source voltages and current.

- Capability for instant-off test (requires smart controller)

- Optional1: Internal electrical resistance

Corrosion Monitoring

Information Provided

- Protection Levels Estimation, Service interruptions, Breakdowns, Anode/bed depletion, fault in cables or connections, CPS effectiveness, faults in cables or connections.

- Optional1: anticipated corrosion rate in the medium.

Variables Measured

- Cathodic Protection Controller Output Voltages and Currents (DC).

- Cathodic Protection Controller Half-Cell Voltage.

- Power source voltages and current.

- Capability for instant-off test (requires smart controller)

- Optional1: Internal electrical resistance

Corrosion Monitoring

Information Provided

- Protection Levels Estimation, Service interruptions, Breakdowns, Anode/bed depletion, fault in cables or connections, CPS effectiveness, faults in cables or connections.

- Optional1: anticipated corrosion rate in the medium.

Variables Measured

- Cathodic Protection Controller Output Voltages and Currents (DC).

- Cathodic Protection Controller Half-Cell Voltage.

- Power source voltages and current.

- Capability for instant-off test (requires smart controller)

- Optional1: Internal electrical resistance

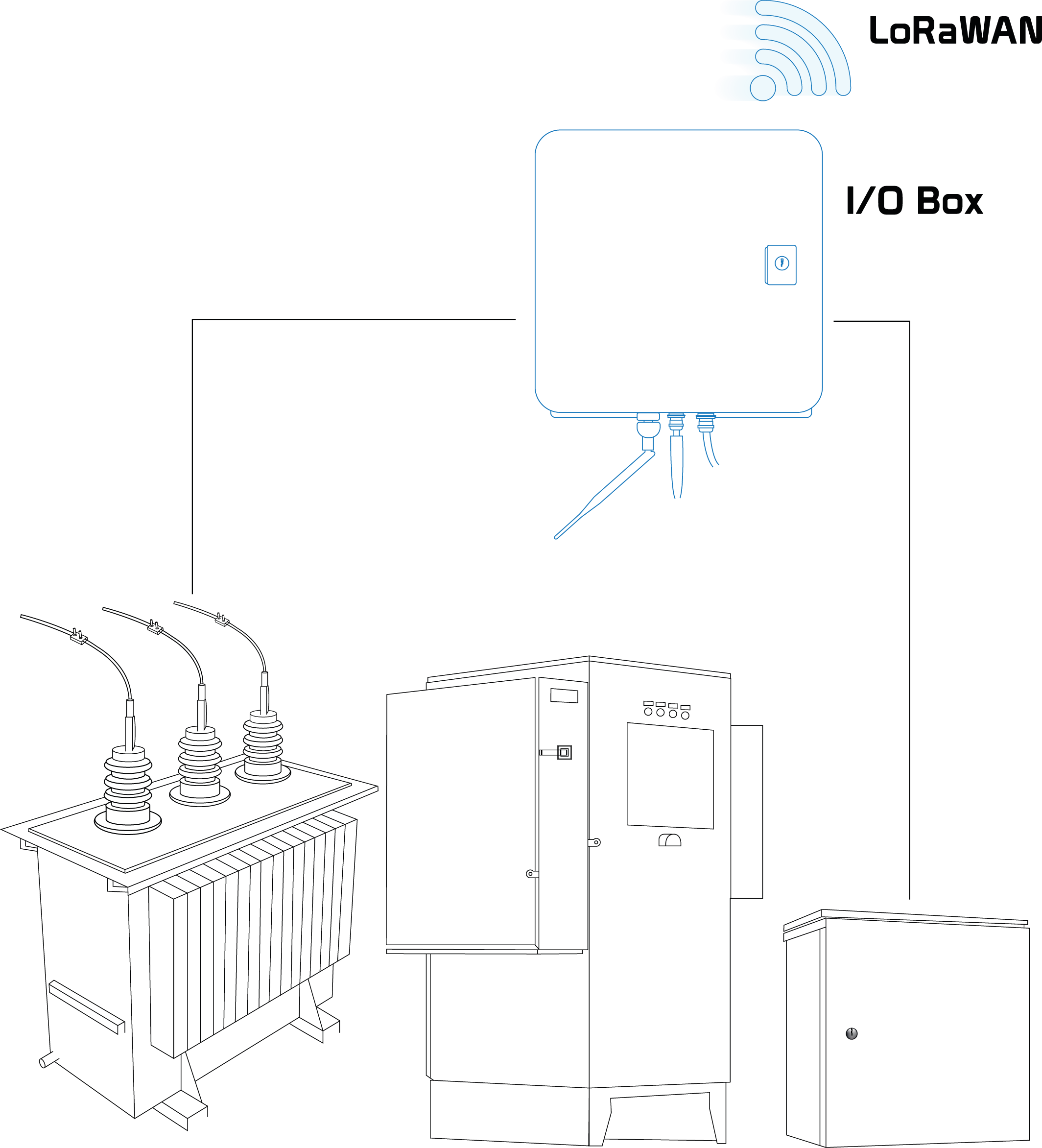

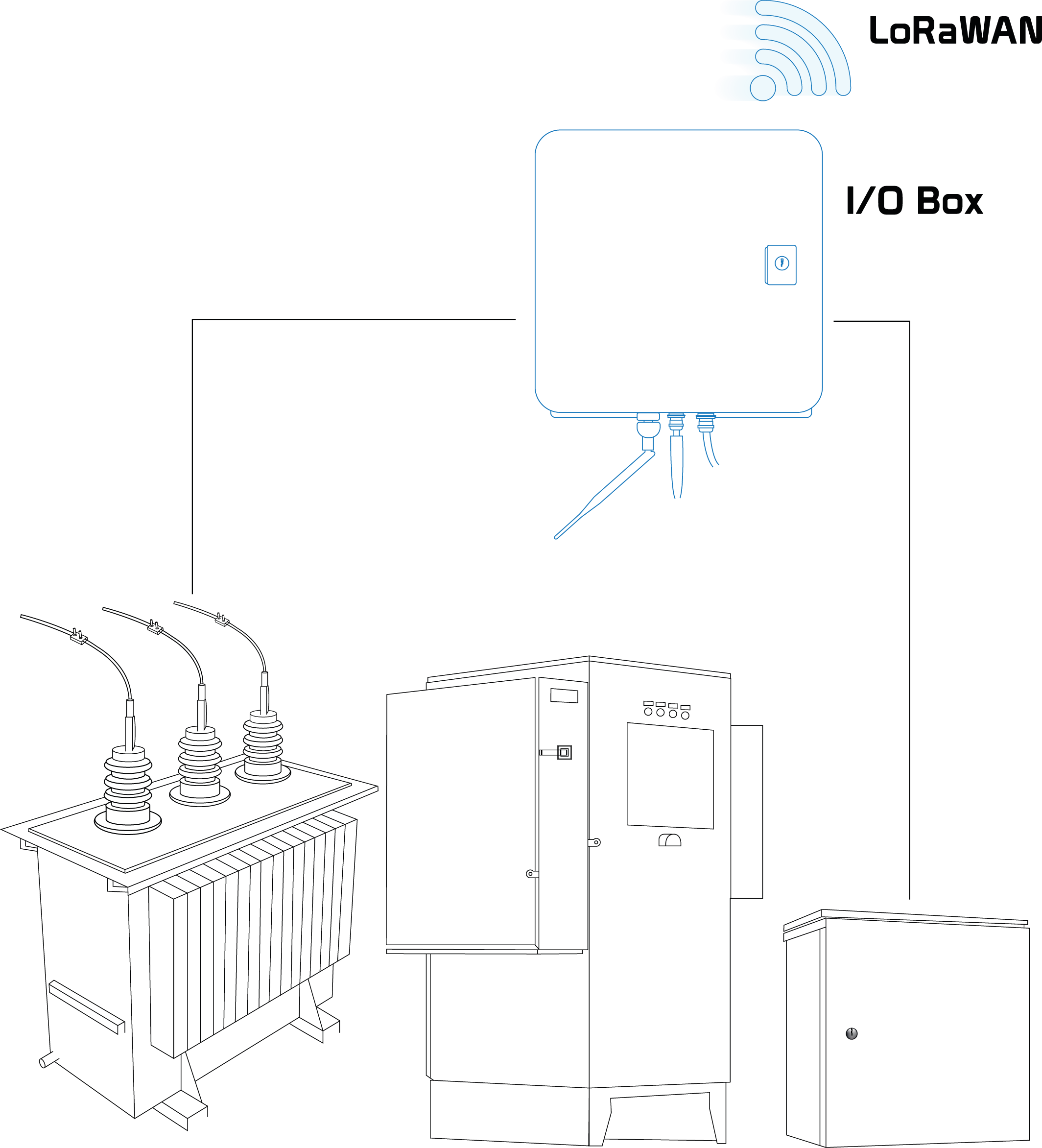

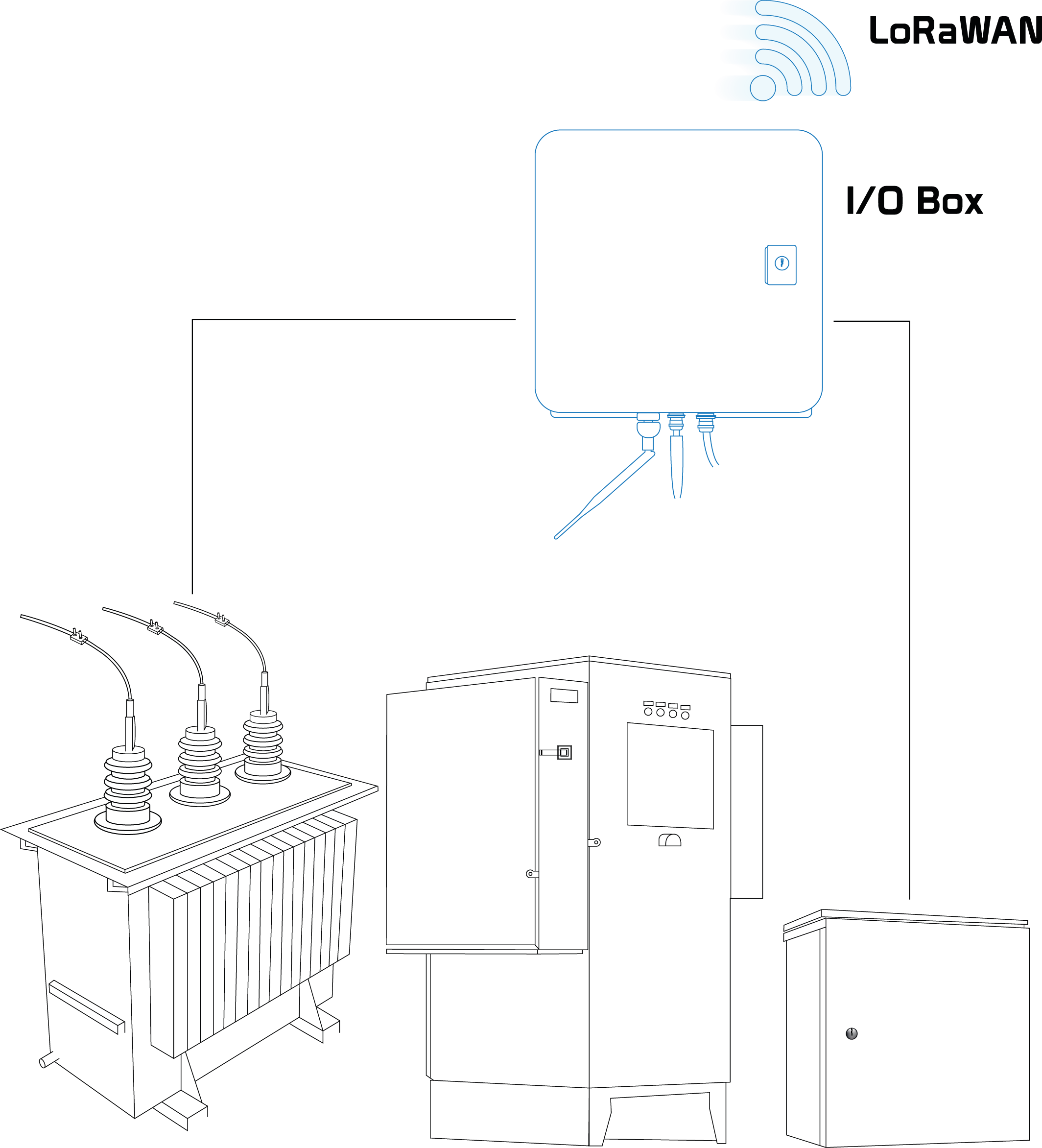

ESP Monitoring and Control

Information Provided

- Real-time remote monitoring for safety and compliance

- Fault detection and notifications.

- Data analysis for performance and energy optimization.

- Remote motor speed control from the operator dashboard. (Frequency control)

Variables Measured

- Transformer: Voltage and Current input, Power factor.

- Variable Speed Drive: Voltage and Current input, Motor Speed, Motor Load, Back Spin detection, Motor Power Monitoring.

- Down hole1: All parameters reported by the controller.

ESP Monitoring and Control

Information Provided

- Real-time remote monitoring for safety and compliance

- Fault detection and notifications.

- Data analysis for performance and energy optimization.

- Remote motor speed control from the operator dashboard. (Frequency control)

Variables Measured

- Transformer: Voltage and Current input, Power factor.

- Variable Speed Drive: Voltage and Current input, Motor Speed, Motor Load, Back Spin detection, Motor Power Monitoring.

- Down hole1: All parameters reported by the controller.

ESP Monitoring and Control

Information Provided

- Real-time remote monitoring for safety and compliance

- Fault detection and notifications.

- Data analysis for performance and energy optimization.

- Remote motor speed control from the operator dashboard. (Frequency control)

Variables Measured

- Transformer: Voltage and Current input, Power factor.

- Variable Speed Drive: Voltage and Current input, Motor Speed, Motor Load, Back Spin detection, Motor Power Monitoring.

- Down hole1: All parameters reported by the controller.